WHETHER IT'S ONE SIMPLE PIECE OF TOOLING OR AN ENTIRE MANUFACTURING FACILITY, HAWK TECHNOLOGY LTD. UTILIZES THE LATEST IN TECHNOLOGY TO HANDLE ANY SIZE PROJECT.

Hawk Technology Ltd provides program management services to customers looking for cost and time-to-market reductions. Our program management service is not only more competitive than other outsourcing options, but also provides a total manufacturing service from conception through product delivery.

Using true concurrent engineering concepts, our program management service allows our design and manufacturing operations to respond to rapidly changing designs, and still reduce lead times and cost from design through manufacturing to product delivery. We can provide program management for any size project utilizing either in-house personnel or by providing on-site support at your facility.

Initial Manufacturing Planning Expertise

- Detailed part processing including load sequences

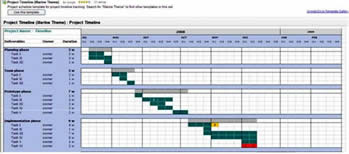

- Project time line with specific milestones

- Safety evaluations and risk analysis

- Lean manufacturing principles

- Cycle time estimates

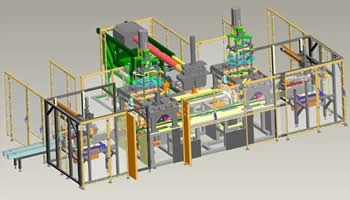

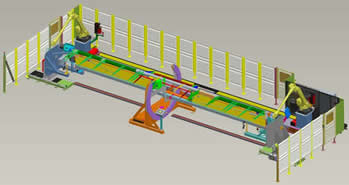

- Floor space layout

- FMEA analysis

- Ergonomics

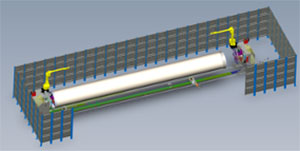

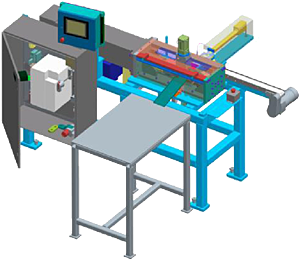

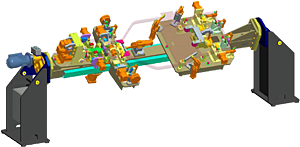

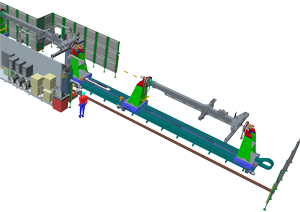

Intelligent Fixture and Machine Design

- 3D Parametric modeling

- Advanced FEA analysis

- Proprietary AI 2D drawing creation (software developed and used by Hawk)>

- Significantly increases efficiency and accuracy of 2D drawings

- Artificial intelligence ensures accuracy of all drawings/schematics created

- RFID used extensively in machine designs

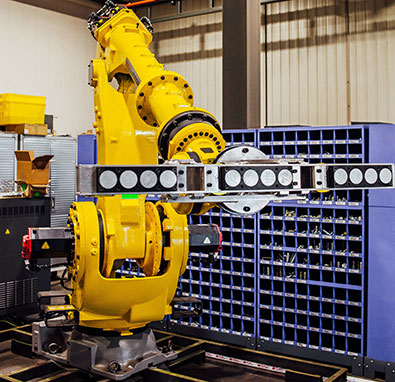

- AI used throughout our cutting edge machine designs

- Weld seam tracking

- Weld seam finding

- AI Vision based part picking/stacking/loading

- Deep machine learning for automated assembly tasks

- Cutting edge machine network design

- ECAT/ProfiBus and others

- EWON Remote Technical Support on ALL machines. Free of charge for every HTL customer. No subscription needed. Learn More Today, Click Here.

-

CNC Program generation from CAD/CAM for increased precision

- ISIR and inspection reports provided

- Milling, turning, boring, and grinding services

- Quick turnaround

- Pick up and delivery is included

- Full suite of conventional machinery

- Latest CNC technology

- Highly skilled workforce

- Toolmakers trained in Pro/E for real time part creation

- Full suite of inspection equipment including 12' FARO arm and 80" CMM

- Testing here and at customer site

- Overhead hoist

- Variety of manufacturing equipment for run off

- Inspection services to measure and analyze production parts

- ISIR, PPAP and other SPC documentation provided

- All tools inspected and shimmed to nominal

- Report provided

- On-site tooling maintenance programs

- Weld development and engineering

- Ergonomic and safety analysis

- Offline robotic programming

- Cutter path generation

- Water jet cutting

- Production CNC

- CMM inspection

- Welding

Prototype Part Machining and Fabrication

Fabrication

Run Off and Tool Tryout Services

Other Services

"I began working with Hawk as a supplier when we were closing our factory. With this closing, I was left with one disaster after the next. At the last minute, we asked Hawk to complete the build of two machines that were started by engineers at another plant. Throughout the build phase, they discovered several design issues that we worked through to improve the machines. They did not hesitate to take on the challenge and supported us in our time of need. I was able to work one on one with their design engineers on several of the changes. They worked weekends and many long hours to complete the machines in a timely manner. Thanks to Hawk, we were able to get back on our feet. Once the machines were installed, they continued to help make improvements and tooling for us."

Customer, Automation Project